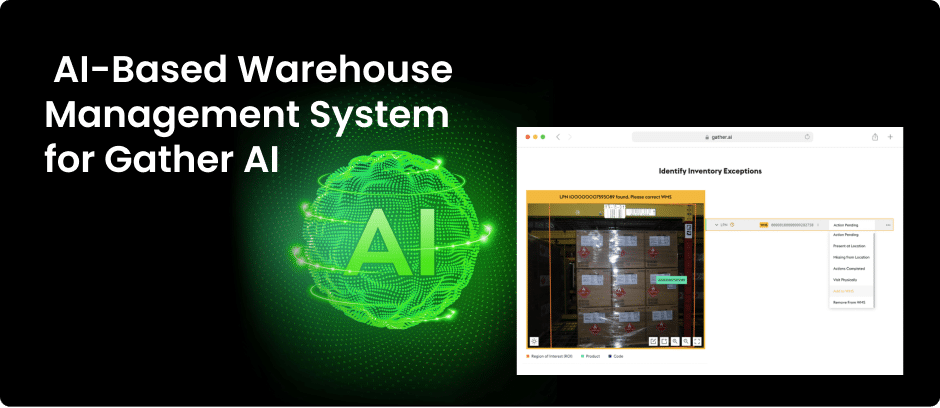

AI-Based Warehouse Management System for Gather AI

Client: Gather AI

Gather AI, a pioneering company in the field of autonomous inventory management, sought to revolutionize warehouse operations through the implementation of cutting-edge AI technology. With a vision to optimize inventory management and streamline warehouse processes, Gather AI partnered with Ayraxs Technologies to develop an AI-based warehouse management system. This case study explores the challenges faced, the AI models implemented, and the transformative outcomes achieved.

| Domain | Challenges | Solution |

|---|---|---|

|

Inventory Accuracy |

Gather AI faced challenges in maintaining high inventory accuracy due to manual counting errors and inefficiencies in tracking stock levels in real time. |

Inventory Tracking: We developed an AI model using Convolutional Neural Networks (CNNs) for image recognition and analysis. This model was trained to accurately identify and count inventory items using images captured by drones and fixed cameras within the warehouse.

|

|

Operational Efficiency |

The existing warehouse operations were plagued by inefficiencies in picking, packing, and restocking processes, leading to increased labor costs and reduced throughput. |

Operational Optimization: For optimizing picking, packing, and restocking processes, We employed Reinforcement Learning models. These models were trained to determine the most efficient routes and methods for warehouse staff and autonomous robots to minimize travel time and reduce operational costs.

|

|

Data Integration |

Integrating data from various sources, such as RFID tags, barcodes, and IoT sensors, into a cohesive system for real-time decision-making was a significant challenge. |

Data Integration: A custom-built neural network was implemented to integrate data from RFID tags, barcodes, and IoT sensors. This model ensured that real-time data was available for decision-making, providing warehouse managers with up-to-date information on inventory levels and locations. |

Results

- Enhanced Inventory Accuracy: The AI-based inventory tracking system improved inventory accuracy by 35%, significantly reducing discrepancies and stockouts.

- Increased Operational Efficiency: The optimized picking, packing, and restocking processes resulted in a 25% increase in throughput, reducing the time required to fulfill orders.

- Lower Operational Cost: Labor costs were reduced by 20% due to the efficient allocation of resources and the integration of autonomous robots into the workflow.

- Improved Data Integration: Real-time data integration allowed warehouse managers to make informed decisions quickly, enhancing overall operational efficiency and responsiveness.

What our clients says

Conclusion

The collaboration between Ayraxs Technologies and Gather AI has significantly transformed warehouse management operations. By developing and deploying advanced AI models, Ayraxs enabled Gather AI to achieve remarkable improvements in inventory accuracy, operational efficiency, and data integration. This case study highlights the potential of AI-driven solutions in optimizing warehouse management systems and underscores Ayraxs Technologies expertise in delivering innovative solutions that drive business success in the rapidly evolving logistics and supply chain industry.

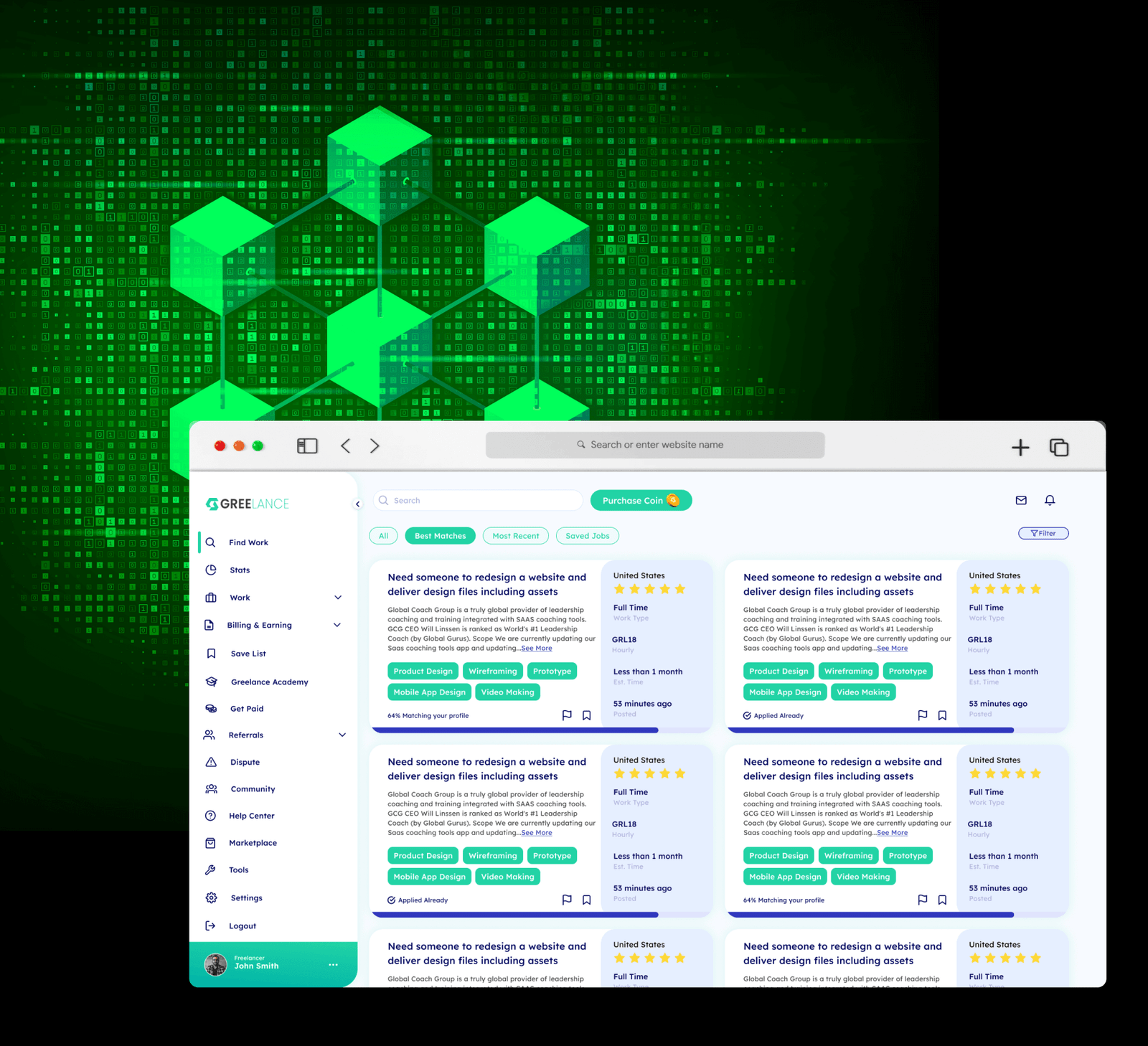

You May Also Like

Artificial Intelligence

AI-Based Warehouse Management System for Gather AI

Artificial Intelligence Blockchain

Enhancing Supply Chain Transparency for Makro Pro

Artificial Intelligence Web Development

AI-Driven Sales Pipeline Enhancement for SalesHoney

Artificial Intelligence Web Development